Your cart is currently empty!

Detail design

1. holes for bolts and pins

Nominal clearances for bolts and non-matching pins are taken according to the table below. By nominal clearance is meant as the difference between the diameter of the round hole and the diameter of the bolt.

Example:

a) for the M12 screw we will design a hole with a diameter of 13 mm

(b) for the M16 screw, we will design a hole with a diameter of 18 mm

(c) for the M27 screw, we will design a hole with a diameter of 30 mm

2. minimum diameter of holes

The minimum diameter of the holes is equal to the thickness of the sheet in which the hole is to be burned.

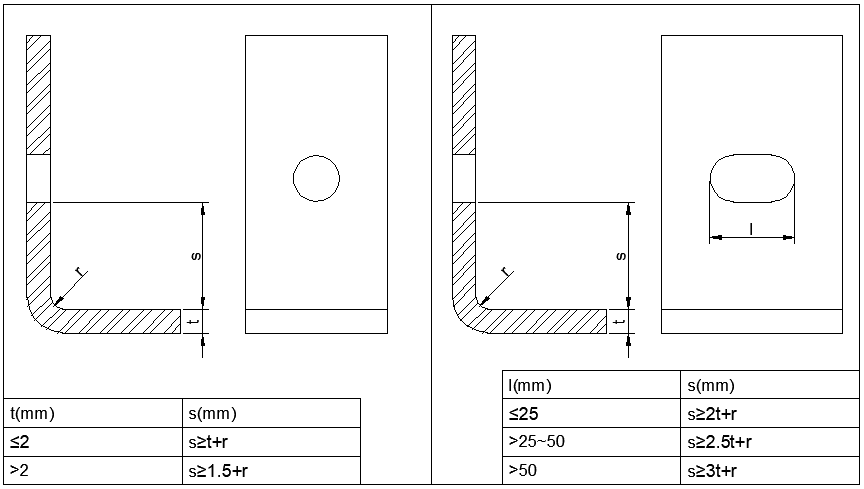

3. minimum distance of holes from the bending line

In order to avoid deformation associated with the hole being too close to the bending line, an offset “s” should be used according to the figure below:

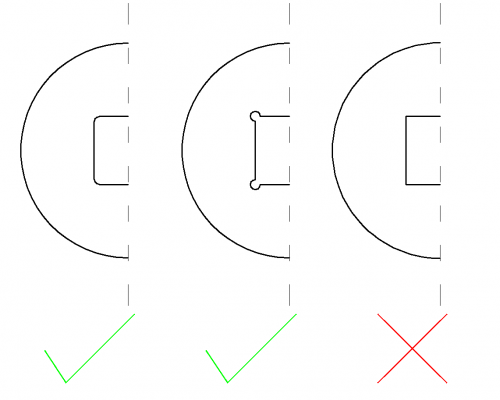

4. inner corners

It is good design practice to round the inside corners. This is to avoid notching and subsequently prevent brittle fracture.