Your cart is currently empty!

Several methods of cutting steel sheets are available in the industry. This ranges from mechanical cutting to waterjet cutting to thermal cutting. Choosing the right technology depends on our needs and expectations, as each method has its own advantages and disadvantages.

In addition, we can divide thermal cutting into:

– oxygen

– plasma

– CO2 laser

– fiber laser

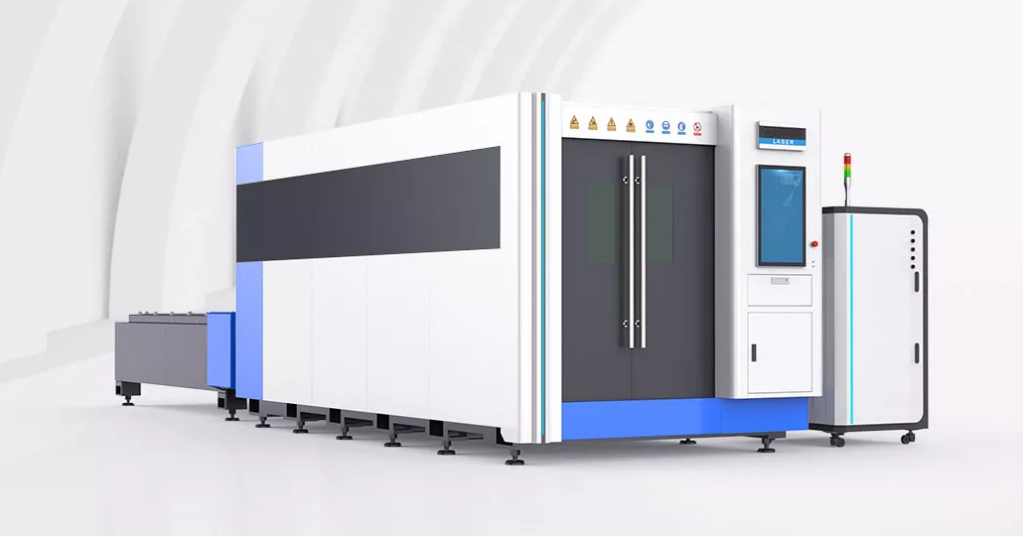

This article will cover fiber laser cutting more extensively.

Diode-source laser cutting technology for steel sheets has come to the industry in earnest circa. 2010, displacing CO2 laser cutting technology in the process. The reason fiber lasers are so popular is that they are much cheaper to operate and use less electricity.

In addition, there is a technical limitation in CO2 lasers to build sources of more than 8 kW. There is no such limitation in fiber lasers, and it is increasingly common to find fiber lasers of 12 kW or more in companies providing cutting services. This, in turn, allows us to perform services even faster, and this translates into increasingly lower cutting costs for the end customer.